Seems like my 7/8n2 updates are getting farther and farther apart.

In any case, I set aside the Contractor's Diesel that I began working on in my last post. I need to do some more research and get more solid dimensions before I continue with it. Also, being a powered unit, I'd like to "solve" all of the electronics and batteries and build the unit around that instead of the other way around.

In the mean time it seems that I've been enchanted by Victorian era English coaches. These quaint little passenger cars range in size from about 16 feet long to over 60 and are typically box shapped. One thing I was happy to find is that in the UK preserving historical lines seems to be something that is taken seriously, and a handful of charming railways are restored and operational...

...just to name a few. An interesting side characteristic is that many of these railways provide support to model railroaders, listing dimensions, characteristics, and other stats on the railway's engines and rolling stock.

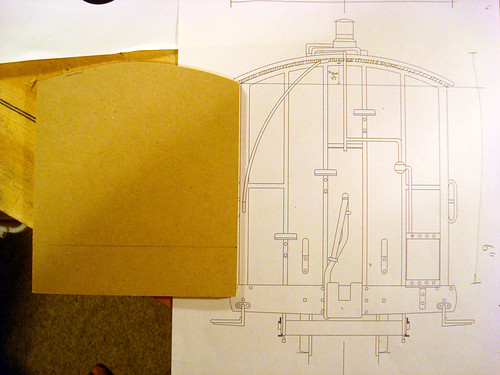

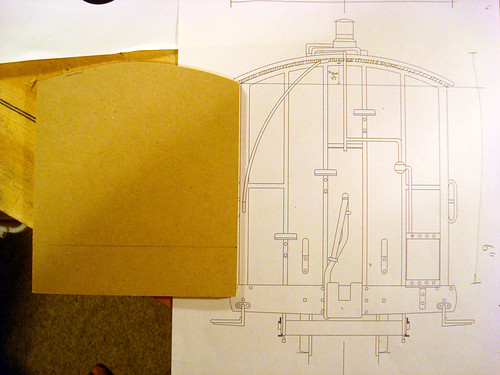

I've taken to attempting to build a 2-axle coach (seating approximately 16) in 7/8n2 scale. The coach I've designed is

heavily based on the Victorian era coaches from Lynton & Barnstaple, however I've shortened them down from full "bogie coaches" into a shorter 2-axle version.

As is starting to become my norm, I did a lot of research and planning before I even began construction. A particularly notable resource in all of this has been this website:

Modeling the Lynton & Barnstaple Railway.

The body is being fashioned out of 1/8" MDF which was leftover from my HOn30 micro-layout's faschia board. Working with it, it's like a cross between cardboard and wood. I'd odd stuff, sometimes easily damaged, very workable, and generates a ton of dust. The jury is out on if I'll ever use this again. On the positive side, a sheet 4" x 2" x 1/8" is only $3 locally making is ridiculously affordable.

Thus far I've managed to cut out the front, back, and one side wall. As seen here is the outer shell of the coach. The exterior will be detailed with strip wood and the interior will be lined with detail as in the prototype, including strip-wood benches.

The walls are given a general shape with an electronic jig saw then cleaned up with sandpaper and files. The windows are being cut by hand with a coping saw, then cleaned up with files and sandpaper. The doors are currently scribbed in about 1/16" deep. I say currently because part of me wants to actually cut them out and make working doors; part of me thinks that will end up being a huge hassle.

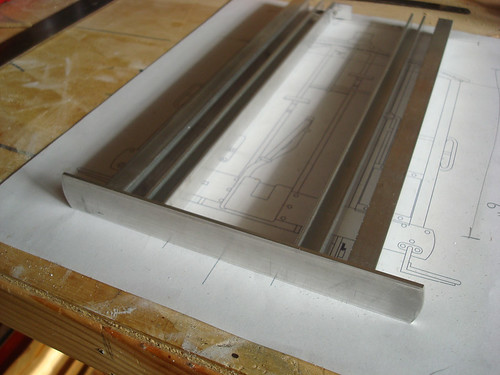

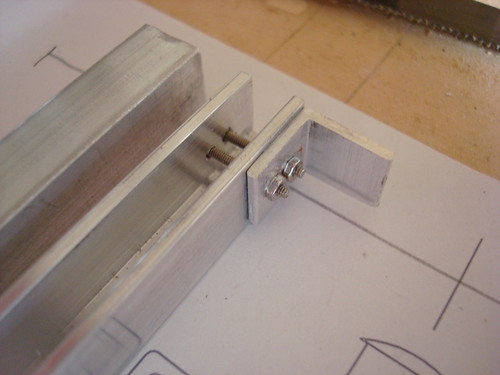

What I need to start planning more of is the chassis. I'm considering building it out of aluminum and cold fastening (nuts/bolts/angles).